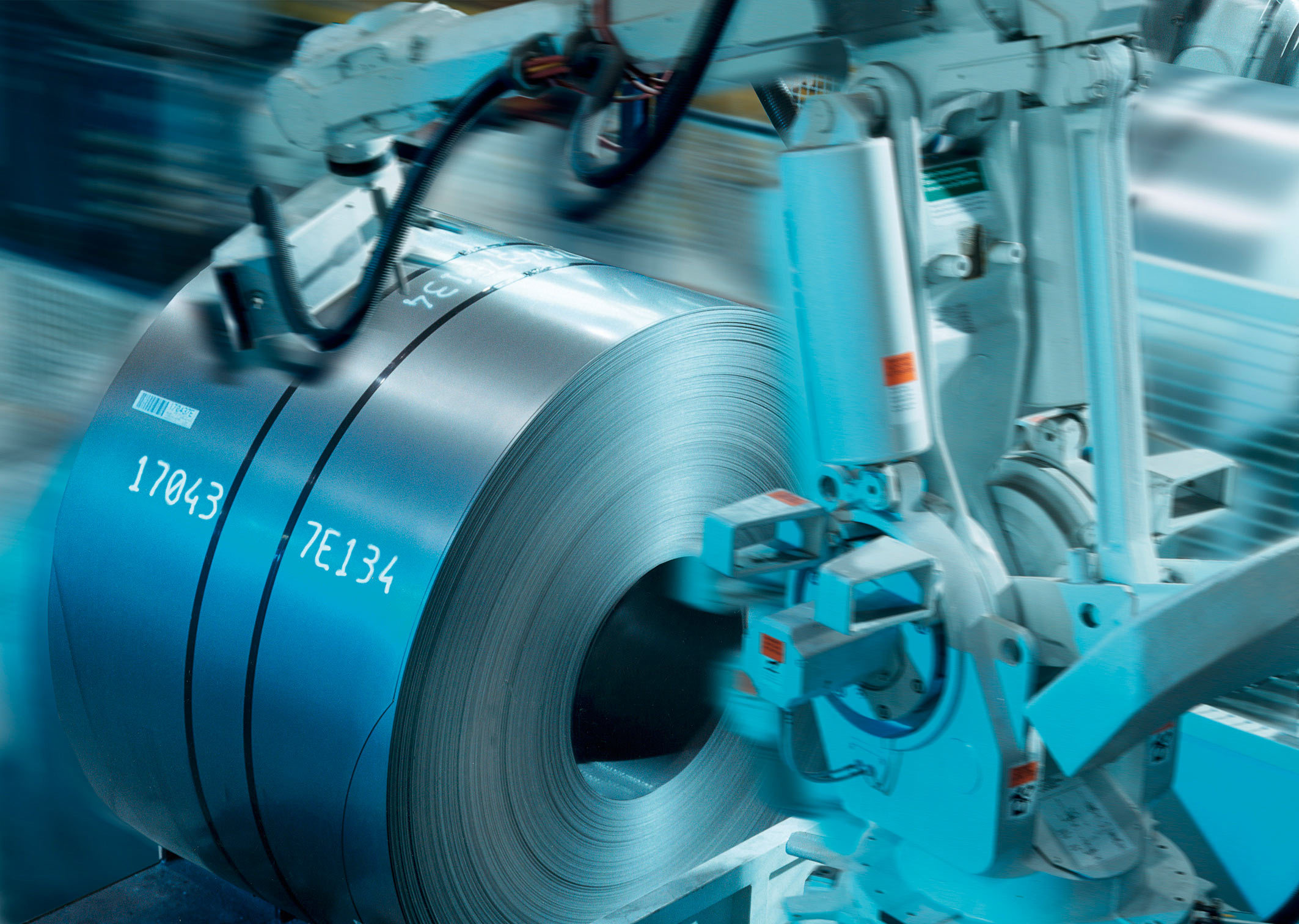

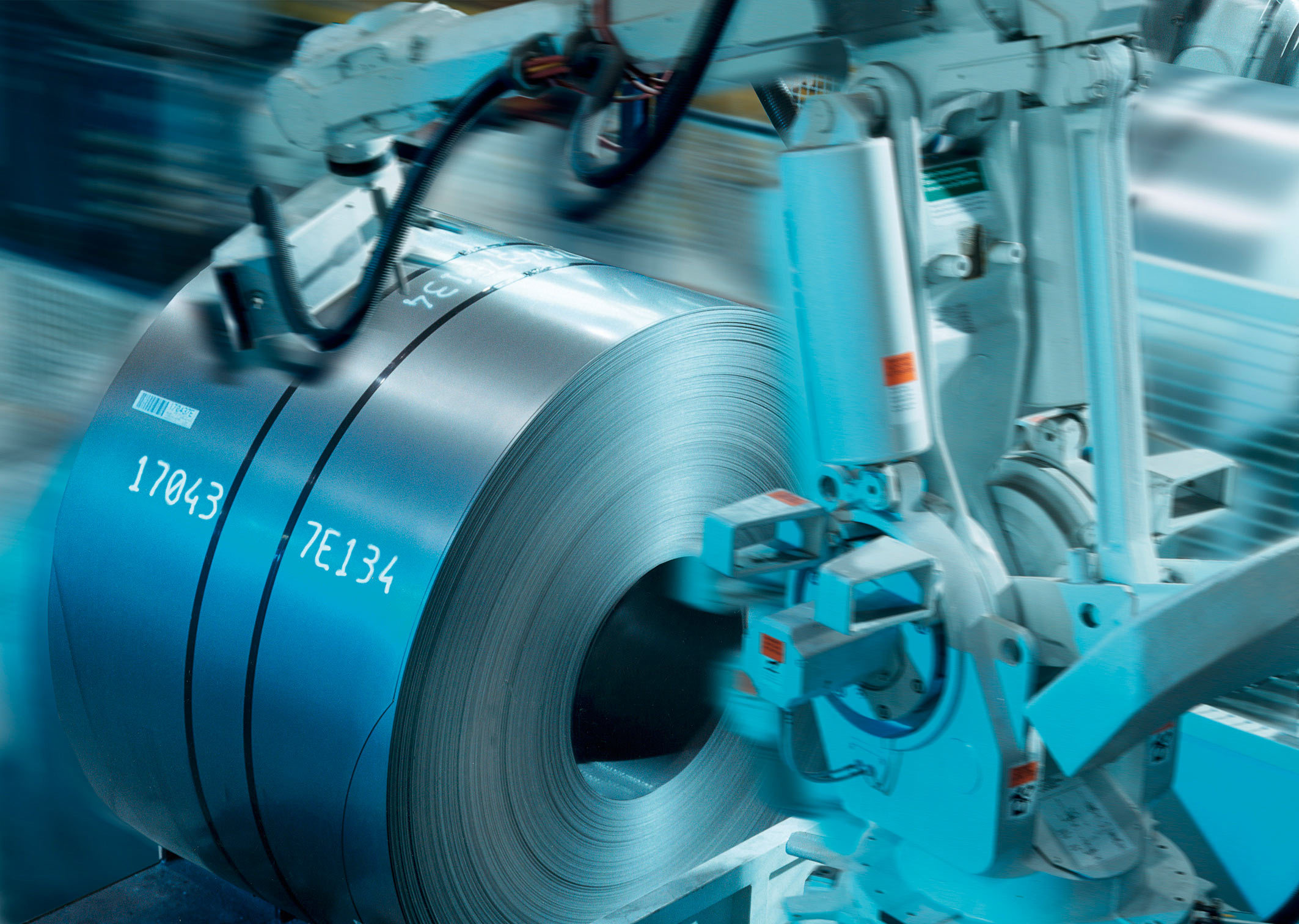

Highly robotized and automated manufacturing

Securing delivery ability to an emerging and rapidly growing market. Our short production time is safeguarding our ability to meet the strictest of deadlines.

MossHydro competitive edge

Established in 1932 and family owned for 3 generations. The production facility used by MossHydro covers 20.000 m2 and employs some 200 workers. The factory has manufactured 3 million pressure vessels. The world’s first serial production facility for stainless steel pressure vessels - operating for more than 40 years. It is one of Scandinavia’s most modern and efficient environmental friendly factories with unmatched daily production capacity for filter housings. Over the decades the factory has received Nordic awards for exceptional environmental efforts.

In-house test facilities

Located in Drammen (Norway), MossHydro has unlimited access to water to run independent tests of products for own developments or specific tests for customer related projects. This give great access and quick turnarounds for any test or verification required. The test facility is located in the harbor of Drammen and is accessible at any time of the year. These facilities have been used in the development of our new filtration technology over the last years.

Highly robotized and automated manufacturing

Securing delivery ability to an emerging and rapidly growing market. Our short production time is safeguarding our ability to meet the strictest of deadlines.

MossHydro competitive edge

Established in 1932 and family owned for 3 generations. The production facility used by MossHydro covers 20.000 m2 and employs some 200 workers. The factory has manufactured 3 million pressure vessels. The world’s first serial production facility for stainless steel pressure vessels - operating for more than 40 years. It is one of Scandinavia’s most modern and efficient environmental friendly factories with unmatched daily production capacity for filter housings. Over the decades the factory has received Nordic awards for exceptional environmental efforts.

In-house test facilities

Located in Drammen (Norway), MossHydro has unlimited access to water to run independent tests of products for own developments or specific tests for customer related projects. This give great access and quick turnarounds for any test or verification required. The test facility is located in the harbor of Drammen and is accessible at any time of the year. These facilities have been used in the development of our new filtration technology over the last years.

Research & development

Under contstruction

Frequently asked questions

We offer water filtration systems for various applications, such as ballast water filtration, clean water filtration, and multistage filtration systems. Our systems range from simple filtration needs to complex multistage filtration requirements.

Yes, we obey to all our customers. You say it you got it. At MossHyrdro we strive to meet the requirements of the customers. This may be from small things like dimensions or placements of flanges, to tailormade requirements for larger solutions.

All filters may need some maintenance from time to time, such as change of simmerings, cleaning of filter screen, replacement of cartridges and membranes, or preservation for extended stop. We can offer repair, service programs, training or simple inspections of the installed systems.

Our filters are durable and built for hash conditions. However there are many external factors that will have small or big impact on the lifespan of the filter. Contact us for further clarifications.

Frequently asked questions

What types of water filtration systems do you offer?

We offer water filtration systems for various applications, such as ballast water filtration, clean water filtration, and multistage filtration systems. Our systems range from simple filtration needs to complex multistage filtration requirements.

Can you customize water filtration systems to fit our specific needs?

Yes, we obey to all our customers. You say it you got it. At MossHyrdro we strive to meet the requirements of the customers. This may be from small things like dimensions or placements of flanges, to tailormade requirements for larger solutions.

What kind of maintenance is required for your water filtration systems?

All filters may need some maintenance from time to time, such as change of simmerings, cleaning of filter screen, replacement of cartridges and membranes, or preservation for extended stop. We can offer repair, service programs, training or simple inspections of the installed systems.

What is the expected lifespan of your water filtration systems, and how often do they need to be replaced or upgraded?

Our filters are durable and built for hash conditions. However there are many external factors that will have small or big impact on the lifespan of the filter. Contact us for further clarifications.